NXaaS in Action: Mission-Critical IoT Connectivity

How Global Manufacturing Relies on NXaaS for Mission-Critical IoT Connectivity

When a global manufacturing company deploys thousands of IoT sensors across hazardous industrial environments, traditional network infrastructure simply doesn’t cut it. From chemical processing plants to steel mills, these sensors must maintain constant connectivity despite extreme temperatures, electromagnetic interference, and physically challenging conditions. This is where Network-Experience-as-a-Service (NXaaS) transforms operations from precarious to predictable.

The Challenge: Connectivity in Hostile Environments

Modern manufacturing facilities present unique challenges for IoT deployments. A single production line might span multiple buildings, each with varying levels of wireless signal penetration. Sensors monitoring pressure vessels operate in electromagnetically noisy environments. Temperature monitors in furnace areas must transmit data through extreme heat. Meanwhile, vibration sensors on heavy machinery face constant physical stress.

For one multinational manufacturer with facilities across 40 countries, maintaining connectivity for 15,000+ sensors became a critical business priority. Equipment downtime costs averaged $260,000 per hour. Predictive maintenance driven by sensor data had become essential to their competitive advantage. But their patchwork of carrier contracts, local ISPs, and on-premises network infrastructure created blind spots—literally and figuratively.

Why Traditional Network Solutions Fall Short

Traditional approaches to industrial IoT connectivity typically involve:

Fixed carrier contracts that lock facilities into regional providers with varying service levels and capabilities. When a plant in Southeast Asia experiences connectivity issues, troubleshooting involves multiple vendors, unclear SLAs, and finger-pointing.

On-premises network management that requires specialized IT staff at each facility. Smaller plants lack the resources for dedicated network engineers, while larger facilities struggle with inconsistent configurations across sites.

Device-level carrier management where SIM cards must be physically replaced or reconfigured on-site. With sensors in hard-to-reach or hazardous locations, this becomes operationally expensive and dangerous.

Limited visibility into network performance at the device level. IT teams learn about connectivity problems only after production issues surface.

The NXaaS Advantage for Industrial IoT

Network-Experience-as-a-Service fundamentally reimagines industrial connectivity by abstracting away the complexity of multi-carrier management, device provisioning, and network orchestration.

Automatic Carrier Switching

NXaaS platforms enable devices to automatically switch between multiple carriers based on signal strength, data rates, and availability. In the manufacturing context, this means a sensor in a chemical plant’s basement can seamlessly shift from Carrier A to Carrier B when signal conditions change—without human intervention and without downtime.

This multi-carrier capability proves particularly valuable in remote industrial facilities where no single carrier provides comprehensive coverage. Sensors maintain connectivity by intelligently selecting the best available network at any given moment.

Centralized Management Across Global Operations

A single management interface provides visibility and control across thousands of devices spanning dozens of countries. Network administrators in the central IT team can:

Monitor real-time connectivity status of every sensor

Configure data plans and policies from a unified dashboard

Troubleshoot connectivity issues remotely without dispatching technicians

Deploy firmware updates across entire sensor fleets simultaneously

This centralization dramatically reduces operational overhead while improving response times. What previously required coordination with multiple regional teams now happens through a single pane of glass.

Intelligent Data Routing and Cost Optimization

NXaaS platforms optimize data transmission paths based on cost, latency, and reliability requirements. A pressure sensor generating critical safety data might prioritize low-latency, reliable transmission regardless of cost. Meanwhile, temperature sensors providing baseline environmental monitoring can use more economical data paths.

This intelligent routing reduced the manufacturing company’s connectivity costs by 37% while improving data delivery reliability for critical sensors by 99.7%.

Edge Computing Integration

Modern NXaaS solutions integrate with edge computing infrastructure to process data locally before transmission. In manufacturing environments, this means:

Reducing bandwidth consumption by preprocessing sensor data at the edge

Enabling real-time responses to safety-critical conditions without round-trip latency to cloud systems

Maintaining operational continuity even during temporary network disruptions

Sensors monitoring hazardous conditions can trigger immediate local alarms while simultaneously transmitting data to central monitoring systems for analysis and long-term tracking.

Real-World Impact: Safety and Uptime

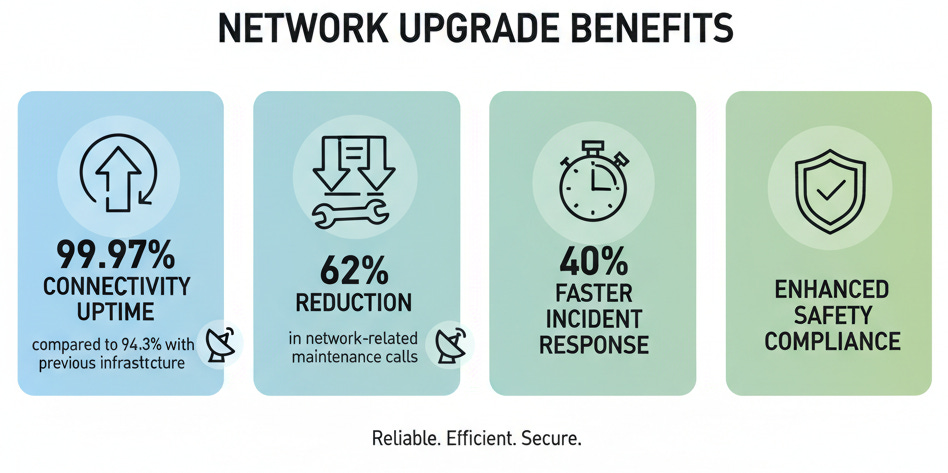

For the global manufacturer, NXaaS implementation delivered measurable improvements:

99.97% connectivity uptime across all facilities, compared to 94.3% with previous infrastructure. This improvement translated directly to more reliable predictive maintenance and fewer unexpected equipment failures.

62% reduction in network-related maintenance calls. Automatic carrier switching and remote management eliminated most field service visits for connectivity issues.

40% faster incident response. When sensors detect anomalies, centralized monitoring and reliable connectivity ensure alerts reach the right teams immediately, regardless of geographic location.

Enhanced safety compliance. Sensors monitoring hazardous conditions now maintain continuous connectivity, creating unbroken audit trails for regulatory compliance.

Beyond Manufacturing: The NXaaS Blueprint

While this case focuses on manufacturing, the principles apply across industries deploying IoT at scale:

Logistics: Fleet tracking across international borders with seamless carrier transitions

Energy: Remote monitoring of distributed renewable energy assets

Smart cities: Municipal IoT deployments spanning varied urban and suburban environments

Agriculture: Soil and crop monitoring across vast rural properties with limited infrastructure

The common thread is the need for reliable, manageable, cost-effective connectivity across geographically distributed devices operating in challenging environments.

Looking Forward

As industrial IoT deployments scale from thousands to millions of connected devices, the network infrastructure supporting these ecosystems must evolve beyond traditional carrier contracts and on-premises management. NXaaS represents this evolution—transforming network connectivity from a fixed cost center requiring constant management into an adaptive service that automatically optimizes for reliability, performance, and cost.

For manufacturers and other industrial operators, the question is no longer whether to adopt IoT, but how to ensure the network infrastructure can reliably support mission-critical operations at scale. NXaaS provides the answer.